Products

We can help you with selection of a chemical formula and provide you with an end product ready to pump depending the application. There are a wide variety of sub-surface conditions we have to deal with, so we simplified them based on common fluid phases – Oil and Water. We will provide you with an engineered solution including laboratory testing and assist you in field operations (procedures, monitoring, testing, etc).

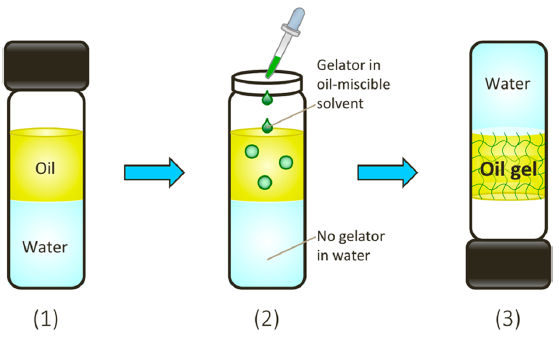

Phase-Selective Gelation of Oil

Adding a gelator in an oil-miscible solvent results in gelation of the oil without the need for heat or shear while leaving the water intact. The oil gel can hold its weight as well as that of the liquid water in the inverted vial.

We can design a Gelator with properties that can be controlled (viscosity, time, gel strength) and place it to suit the application. We can also degrade the gel as required depending on the application.

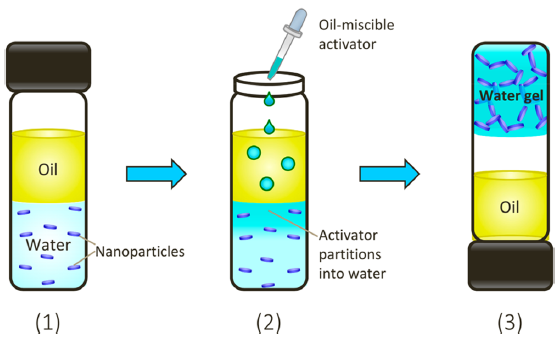

Phase-Selective Gelation of Water

Initially, disklike nanoparticles of laponite are stabilized in the water phase, which is then contacted with the oil. An oil-miscible activator (e.g., butanoic acid) is then added to the oil. Some of the activator partitions into the water, whereupon it activates nanoparticle assembly into a gel. The water is thereby transformed into a gel without the need for heat or shear while the oil is left intact.

The latest product for water phase gelation is shown above. There are other products that directly work with water are available as well. Our Gelators for water phase can be controlled (viscosity, time, gel strength) and they can be placed either alone or in combination of an Oil gelator depending on the application.